Prototyping

WHAT IS PROTOTYPE CASTING?

Prototype casting allows engineers and designers to evaluate and refine their concepts before full production. It involves crafting a limited set of parts to validate a design or process, acting as an essential step in spotting potential design glitches, material inconsistencies, or procedural inefficiencies.

Development and Design

Epcor utilizes industry leading simulation software for each program launch to fine tune design for guaranteed part quality in our prototyping and full production process.

Problem Solving at the Start

By visualizing the metal flow, cooling, and solidifying processes, we can anticipate and address potential challenges before they arise.

Cost and Risk Mitigation

By simulating parts upfront, we drastically reduce the risk and total costs across your program’s life.

Rapid Production Readiness

This analysis ensures quick turnarounds without sacrificing quality, helping you stay ahead.

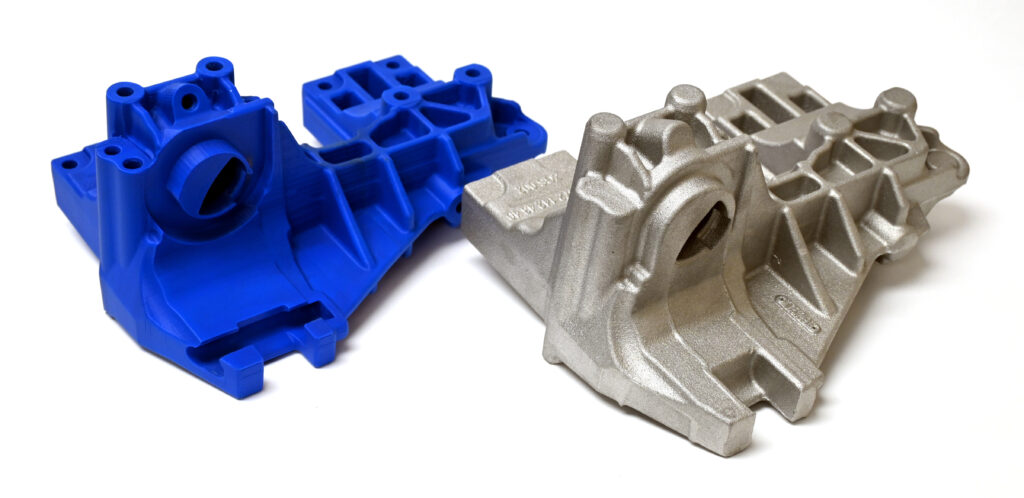

Prototyping to Production

Ensure your prototype development design can be made consistently in a cost effective production setting.

Production Intent ProcessesWe provide reassurance that the parts being produced for design validation are representative of what they will see in production.

Repeatability

All our prototypes are produced in a complete production foundry and not a testing environment, to verify the repeatability of your part for low, medium, or high production runs.

Quick Turnaround

3D printing is ideal for quick changes, as only the CAD file needs to be updated. No need for expensive tooling. 3D printing gives the speed and flexibility to make the prototypes you need to verify part performance.

Pattern Shop

Our pattern shop works directly with development and design engineers, ensuring each pattern is made for exact castability.

Gating System

Design specifications are brought to the pattern makers to build the channels through which molten metal will flow into the mold’s cavity for defect-free casting. The pattern incorporates the gating system design to make sure the molds created include the necessary channels (sprues, runners, and gates).