Excellence in Aluminum Sand Casting and Prototyping

From industrial components to high-performance parts, expect repeatability and quality in every casting.

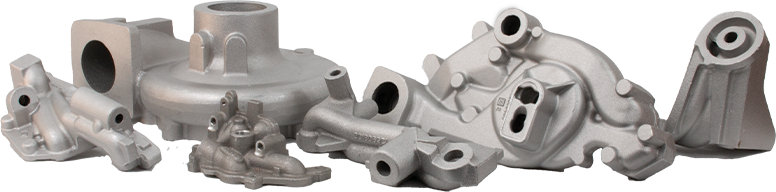

Crafting high-quality castings in all sizes and complexities

Epcor Foundry offers a wide array of production capabilities, from intricate core designs to deep draw, automatic molding, and cellular processes. Our expertise in complex core designs ensures repeatability and strength within your casting. Our deep draw capabilities efficiently produce components with deep pockets and complex geometries. Furthermore, adopting cellular production techniques optimizes workflow efficiency and enables seamless coordination across different manufacturing stages. Our diverse production capabilities empower us to deliver creative solutions that meet the most challenging requirements.

Casting and Manufacturing Capabilities

From small components to heavy and large castings, Epcor Foundry excels in crafting high-quality leak-tight castings in all sizes and complexities

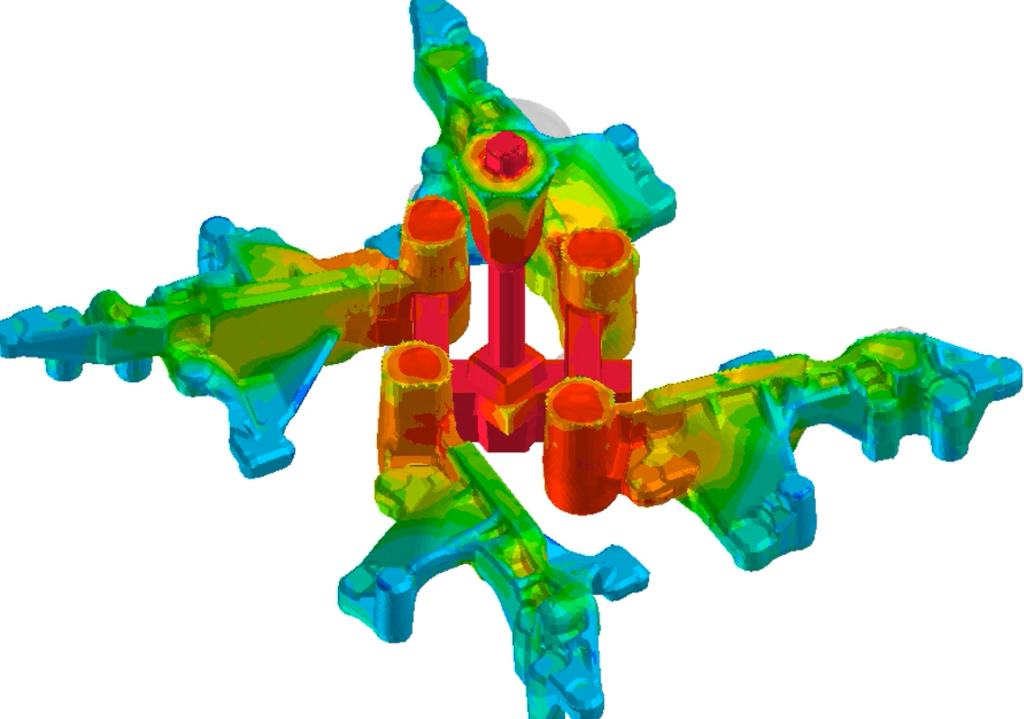

Simulation

We use advanced simulation software to model and analyze the casting process, ensuring our predictions are accurate and reliable. These simulations help us improve our methods, making our launches more efficient and shortening our time to market. Clients can rely on Epcor Foundry for simulation solutions that cut costs, increase efficiency, and deliver better aluminum castings.

Molding

Our automatic molding lines streamline production, ensuring consistency and repeatability with every mold. With melt rates surpassing molding output, we achieve peak throughput without compromising on the integrity of our products. The integration of robotic pouring further enhances our capabilities, ensuring uniformity and accuracy in every pour. Moreover, the tenure of our employees brings a wealth of knowledge and expertise to every project, guaranteeing that each casting meets your expectations.

Finishing

Epcor Foundry offers advanced production capabilities, including PLC-controlled core removal, 5-axis CNC saws, trim cells, and tumble blasting. PLC core removal allows for quick and precise core removal for high quality and consistency. 5-axis CNC saws make intricate cuts on complex geometry. Trim cells streamline the trimming and finishing processes, and tumble blasting gives a uniform finish. Our rigorous inspection procedures guarantee the highest quality standards are met before components leave our facility.

Quality Systems

Epcor Foundry is committed to quality. We hold ISO and IATF certifications as proof of our adherence to rigorous international standards. These certifications ensure we always provide our customers with industry leading aluminum sand castings. Our lab can thoroughly test and analyze materials and finished products to ensure adherence to the strictest quality criteria. PLC controls and monitoring systems throughout our production processes guarantee precision and reliability at every stage. Our dedication to quality means our customers receive nothing but the best in each container we ship to you.

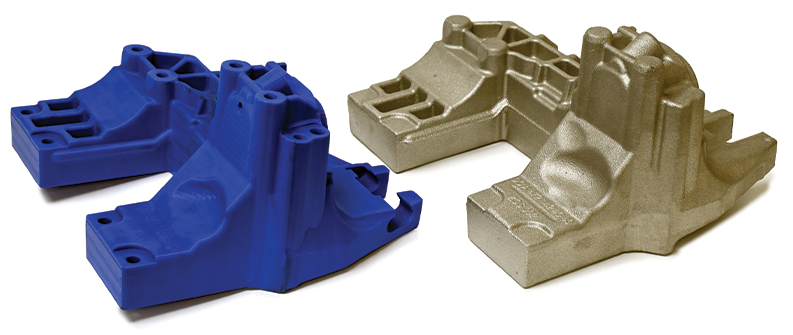

Prototyping

Our approach to prototypes and advanced technology expedites the prototyping phase, turning your ideas into physical parts. Advanced simulation tools and agile methodologies allow for quick adjustments and validation, resulting in quickly refined prototypes. Cut down on lead times and accelerate time to market for your products.

Our Associations

Epcor Foundry brings solutions where others struggle.

With over 75 years of experience, Epcor Foundry understands complex aluminum castings, tackling projects that others shy away from. A comprehensive approach allows Epcor to deliver the lowest cost U.S. sourced castings without compromising quality. Our focus is on solving your manufacturing needs with highly specialized application-based solutions.

Want to learn more? Submit the form below, and let’s talk!

Let's Discuss Your Project

News & Articles

One Team. One Goal. Proven Results.

One Team. One Goal. Proven Results.

Generations of experience, poured into every part.

Certified Excellence, Domestic Peace of Mind

From prototypes to production, EPCOR Foundry delivers U.S.-made aluminum castings with world-class precision and engineering.

Custom Castings. No Complications.

At EPCOR Foundry, we believe that sourcing the right casting solutions should be simple. Whether you need leak-tight thin-wall castings, high-performance parts, municipal castings, or custom components, we make it easy to