News

One Team. One Goal. Proven Results.

One Team. One Goal. Proven Results.

Generations of experience, poured into every part.

Certified Excellence, Domestic Peace of Mind

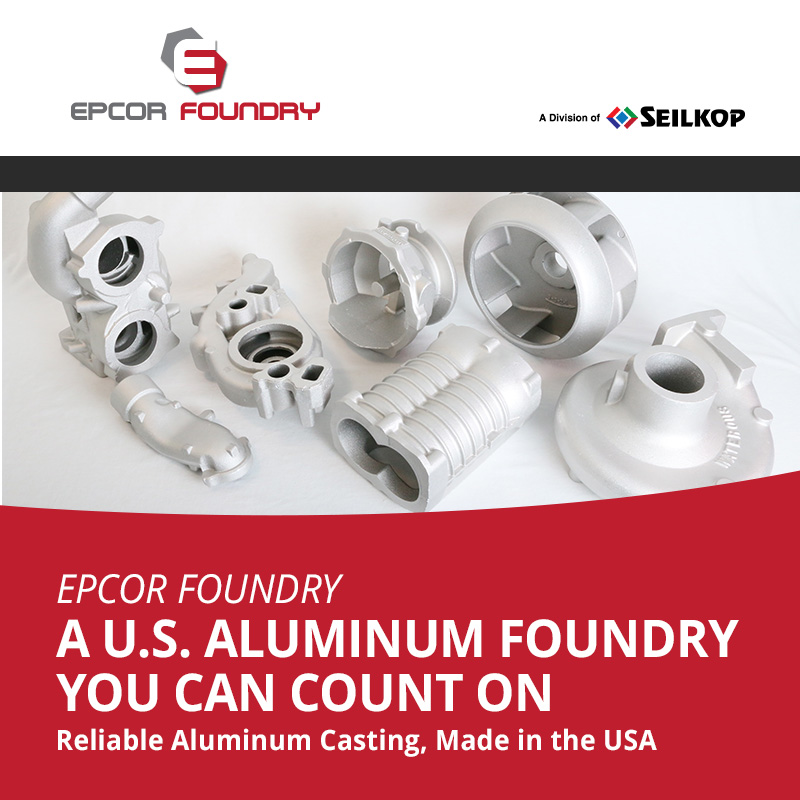

From prototypes to production, EPCOR Foundry delivers U.S.-made aluminum castings with world-class precision and engineering.

Custom Castings. No Complications.

At EPCOR Foundry, we believe that sourcing the right casting solutions should be simple. Whether you need leak-tight thin-wall castings, high-performance parts, municipal castings, or custom components, we make it easy to get exactly what you need—quickly, reliably, and cost-effectively.

Reduce Supply Chain Risks – Source Aluminum Castings Locally

Since 1946, Epcor Foundry has been delivering high-quality aluminum castings for industries that demand precision and reliability. As a trusted domestic supplier, we help businesses avoid the risks of overseas sourcing while ensuring consistent pricing and dependable service.

3 Ways Epcor Delivers Foundry Excellence

At Epcor Foundry, we know that productivity and success in foundry operations come from overcoming critical challenges–not just casting metal.

Achieve Manufacturing Excellence with Certified Quality & Expertise

Partner with us for top-tier quality, comprehensive support, and innovative manufacturing solutions.