News Archive

Advanced Technology & Processes to Deliver Highest Quality Castings

Epcor is committed to continued capital investment in automation technology, process improvement, and lean manufacturing. This enables us to provide you with the highest-quality aluminum castings at competitive prices.

Our Program Management Includes

- Advanced Product Quality Planning

- World Class Tooling And Casting Simulation

- Engineering Design

- IATF 16949:2016AND IS0:9001:2015 Certified

EQUIPMENT

Our DISA Match and SINTO molding machines are the most precise and technologically advanced, optimizing mold quality and uptime to provide you with an uninterrupted supply of castings to keep your production lines running. Our shorter lead times put castings in your hands sooner.

We have the resources to solve your casting challenge.

Need an expert to solve your toughest aluminum casting challenges?

The benefits of working with Epcor Foundry and our in-house tooling division are substantial and critical to partners across many different markets.

- Flexibility – Ability to make timely decisions in-house and offer the solutions needed whether you require new tooling builds or are resourcing tooling.

- Single-Point Communication – The ability to communicate with the same people in charge at every phase of your project.

- Technical Resources – Our simulation experts solve problems on the front end of the casting launch to assure success throughout the life of the program.

- Speed – Agility to accommodate your needs, especially when time constraints are at hand.

How can we help you with your project?

What is your aluminum casting challenge?

We have the solutions!

In the casting world today, we hear about many problems such as supply chain risks, lead times, and line down threats. Companies are on the move in search of a viable solution, but what steps need to be taken in order to make the best foundry decision for your company?

Part 2 - Does your foundry possess the automated processes and controls needed in today’s stringent manufacturing requirements

Epcor has solutions such as:

- Best practices in automatio

- PLC based monitoring and control of all internal processe

- Continuous screening of sand systems, a critical part of achieving the highest quality casting

- Automated 5-axis CNC saw and trim cells for precision cutting and finishin

Thank you for trusting Epcor Foundry. Let's talk about your challenges!

What are your aluminum casting challenges?

We have the solutions!

In the casting world today, we hear a lot of keywords such as supply chain risks, time constraints, and line down threats. Companies are on the move in search of a viable solution, but what steps need to be taken in order to make the best foundry decision for your company?

Does your foundry have the necessary engineering, quality, and customer service expertise to support your needs?

- Epcor is IATF 16949:2016 certified.

- Our in-house foundry tooling division allows complete control and flexibility when speed-to-market is so critical.

- Epcor's history in aluminum sand casting involves high-level engineering with the most complex casting designs in the industry.

- Our teams are dedicated to satisfying customer needs from the point of purchase order, project launch, through mass production.

Thank you for trusting Epcor Foundry. Let's talk about your challenges!

A World Class Foundry such as EPCOR Can Help You Stay Ahead of Competition and Win Business

- Quality – Epcor is IATF 16949:2016 certified, the automotive industry's most widely used international standard for quality management.

- Engineering support and expertise includes in-house simulation and pattern division allowing complete control and flexibility, critical where timing and speed-to-market are of the essence.

- Complex aluminum castings for various industries - highly-cored / pressure tight applications are where we excel.

- Committed to continued capital investment in automation technology, process improvement and lean manufacturing.

Let's Win Your Next Project – Together!

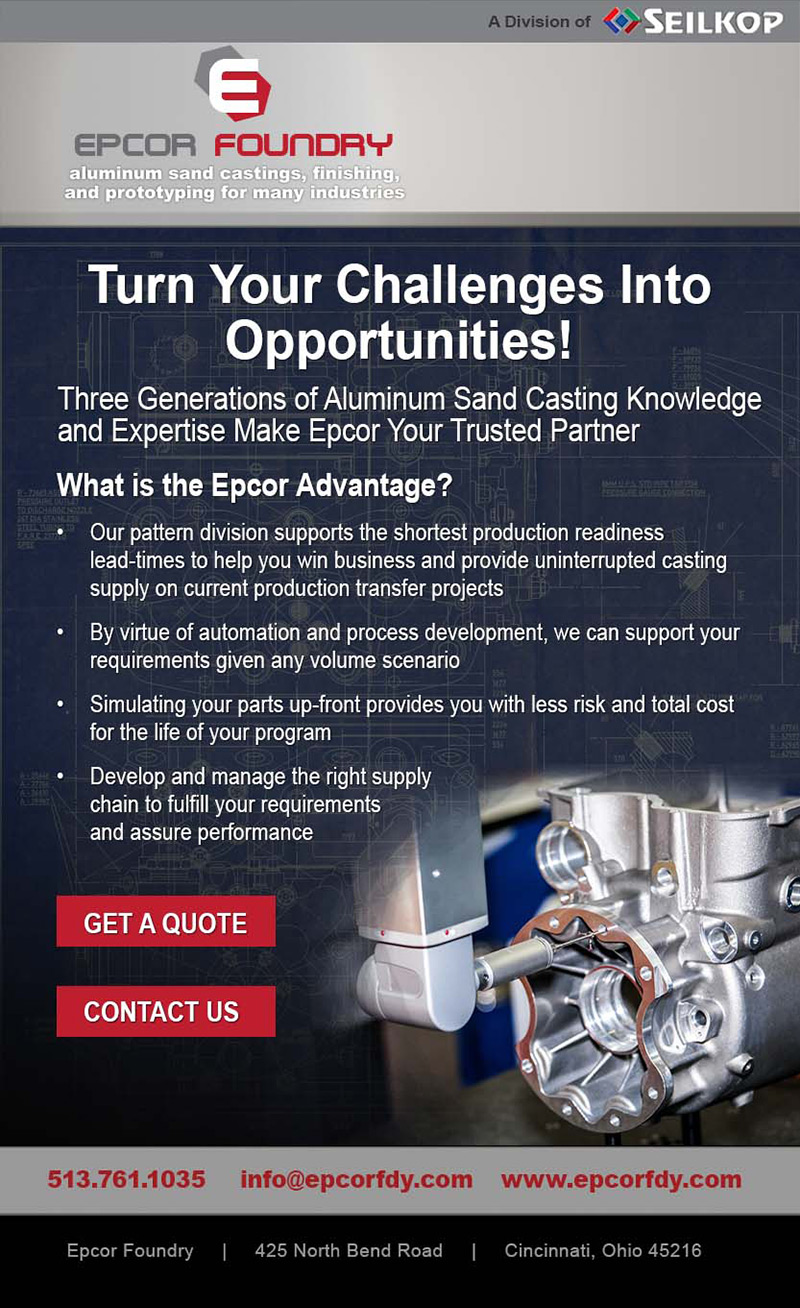

Turn Your Challenges Into Opportunities

Three Generations of Aluminum Sand Casting Knowledge and Expertise Make Epcor Your Trusted Partner

What is the Epcor Advantage?

- Our pattern division supports the shortest production readiness lead-times to help you win business and provide uninterrupted casting supply on current production transfer projects

- By virtue of automation and process development, we can support your requirements given any volume scenario

- Simulating your parts up-front provides you with less risk and total cost for the life of your program

- Develop and manage the right supply chain to fulfill your requirements and assure performance

RESHORE

Now is a great time to look at bringing your castings back to the U.S.!

Have questions about reshoring aluminum sand casting work?

Is the timing right for a solid US-based alternative solution?

Epcor Foundry has the resources you need to make a successful transition, especially those challenging complex applications that aren’t for everyone. Whatever your industry, let us help you!

Navigating the Road of Casting Manufacturing Doesn't Have to be Difficult

Epcor provides you with the best technical and human resources to accomplish your manufacturing goals

- Three generations of casting manufacturing innovation and integrity

- Engineering led/people-oriented

- Process improvement through automation and team training/education

- In-house simulation, tooling design and manufacturing

WELCOME TO EPCOR FOUNDRY

Ready for a solid partner from launch to production on new and transfer projects

Program Management:

- Advanced Product Quality Planning

- Quality Certified to IATF 16949:2016

- Full Engineering Resources

- World Class Tooling and Casting Simulation

Our transparent launch operation keeps you informed so program management is one less thing you need to worry about.

Stringent automotive expectations demand high level process controls –

Epcor brings these standards to all industries

We never stop producing quality components for you.

The importance of aluminum in automobiles and commercial vehicles is ever-increasing due to many industry advantages which include lighter weight, complexity and design flexibility. Regardless of your industry or product line, Epcor can offer you the standards you need from a supplier. Let us show you how!

Do you have a supplier preventing you from meeting your customers orders?

We can help

- Shortest production lead times to help you win new programs.

- Maintain supply to your customers on current projects.

- Absolute control of foundry tooling division to ensure seamless transfer tooling adaptation.

Please contact us to discuss your specific needs.

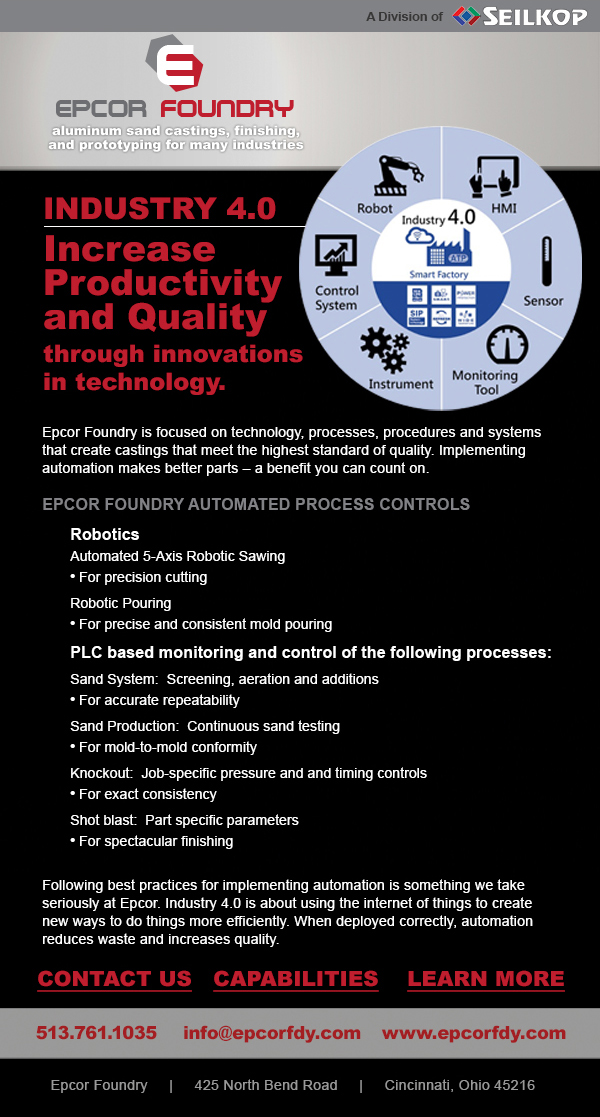

INDUSTRY 4.0

Increase Productivity and Quality through innovations in technology.

Epcor Foundry is focused on technology, processes, procedures and systems that create castings that meet the highest standard of quality. Implementing automation makes better parts – a benefit you can count on.

EPCOR FOUNDRY AUTOMATED PROCESS CONTROLS

Robotics

Automated 5-Axis Robotic Sawing

- For precision cutting

Robotic Pouring

- For precise and consistent mold pouring

PLC based monitoring and control of the following processes:

Sand System: Screening, aeration and additions

- For accurate repeatability

Sand Production: Continuous sand testing

- For mold-to-mold conformity

Knockout: Job-specific pressure and and timing controls

- For exact consistency

Shot blast: Part specific parameters

- For spectacular finishing

Following best practices for implementing automation is something we take seriously at Epcor. Industry 4.0 is about using the internet of things to create new ways to do things more efficiently. When deployed correctly, automation reduces waste and increases quality

Get the Quality You Expect From Epcor!

Epcor Is Opportunity

Questions about retooling or resourcing current aluminum casting programs?

Faced with complex aluminum casting challenges?

Please allow our team to help you develop the solution right for your company!

IATF 16949:2016 CERTIFIED

VISION. TEAMWORK. UNITY. YOUR TRUSTED SOURCE FOR QUALITY

IATF 16949:2016 was published by the IATF and replaces the current ISO/TS 16949, defining the requirements of a quality management system for organizations in the automotive industry.

WHY THIS MATTERS

Achieving this level of certification means our customers are ensured that they are purchasing the highest quality parts from a manufacturer dedicated to defect prevention, reduction of variation, and waste in the automotive industry supply chain.

When Hot and Cold Isn't Bad!

Pressure Tight/Leak Tight Requirements? Stringent Field Applications?

These are familiar terms in many US markets such as Heat Exchangers and Air/Fluid Filtration. Epcor is proud to be supporting numerous tier 1 and OEM customers on the most challenging casting applications in these segments

- EXTENSIVE COMPREHENSION OF LEAK TIGHT requirements for air and fluid movement

- IN-HOUSE CASTING SIMUALTION provides the best opportunity to minimize porosity and yield a solid casting

- WE MANUFACTURE covers, oil/water cooler components and housings for critical industrial application

Diesel Engine Innovation Takes Epcor Foundry Into New Market Segments

Diesel engines have always been critical in the toughest heavy and long haul applications. Now, diesel engines are gaining increased interest for their improved carbon emissions and fuel efficiency making them a welcomed addition to passenger vehicle and light-duty platforms.

Epcor is proud to be a critical part of this picture supporting numerous Tier 1 and OEM customers on the most challenging casting applications in this arena.

- LEAK TIGHT

applications for air and fluid movement - WE MANUFACTURE

turbo and supercharger components, manifold and inlet systems, oil/water cooler components and housings

Let Epcor Foundry Be Part of the Building Blocks of Your Success!

- Superior Tooling Designed and Built In-House

- Three Generations of Tooling and Parts Making Experience

- Shortest Lead Times in the Industry

Tell Us What You Need!

Epcor understands the key components of a successful operation. Partner with Epcor and see why we are

YOUR TRUSTED SOURCE FOR QUALITY

Customers Come First at Epcor Foundry!

Now more than ever, customers require a casting supplier to:

- Lower costs by reducing part complexity.

- Provide the lowest total cost US-sourced castings.

- Offer the best solution for shortest production readiness lead times to help you win new programs.

- Maintain supply to your customers on current (transfer) projects.

We are here to help YOU!!

Please contact us to discuss your specific needs.

We Turn Design Challenges into Opportunities

As an experienced global leader in aluminum casting technology – we've tackled the projects that others shy away from while maintaining quality

What is the Epcor Advantage?

- Lower costs by reducing part complexity

- Optimize process parameters utilizing simulation software

- Provide the lowest total cost US sourced castings

- Shortest production readiness lead times to help you win new programs

- Work in conjunction with our sister company, Hitech Shapes Designs, to assure uninterrupted casting supply on transfer programs

Our precision craftmanship for complex and highly cored leak-tight aluminum castings gives you the competitive advantage you need.

Tell Us About Your Casting Challenges.

We Have the Solutions.

While many of you are working from home, we are here to help you with your new casting designs. The Epcor engineering team is here to provide solutions for some of your toughest challenges. Whether you need a second look at a complex aluminum casting or are looking to redesign an existing part - we can help.

While businesses are being disrupted globally, we can help you make the most of a slower period.

American Made, Globally Trusted

Thank you for your business and partnership and we look forward to assisting you through these unprecedented times.

CHARGING UP PRODUCTION

Epcor expands its production footprint in the Electric Vehicle segment. Let us work with you to expand your Electric Vehicle market share.

AMERICAN MADE.

GLOBALLY TRUSTED.

At Epcor, we turn design challenges into opportunities. Our precision craftsmanship especially for complex and highly cored leak-tight aluminum castings is a skill that few can emulate. As we enter 2020, we will use our design and engineering skills to give you the competitive advantage you need for the highest performing aluminum parts.

We are your foundry of the future.

Happy New Year,

Dave Seilkop

Midwest Design-2-Part Show

Visit Epcor Foundry & Seilkop Divisions at Booth #506

Midwest Design-2-Part Show

November 6 & 7, 2019

Indiana Convention Center • Indianapolis, IN

Free Registration: Click Here

Transferred Tooling & On-Time Delivery is not an Oxymoron

Epcor has an exceptional history of maintaining casting supply when tooling is transferred to us. Our integrated quality driven processes include an in-house tooling facility and adapter plates which allow your patterns to seamlessly fit our machines.

Epcor Foundry is ready to help you maintain an uninterrupted supply of castings to keep your productions lines running. Our diverse background, years of experience in tooling transfers, and strong history of financial stability are here to support you.

- In-House Tooling

- Robotic Automation

- High Speed Molding

- DISA & Sinto Machines

- CNC Finishing

- Rapid Prototyping

- ISO/IATF 16949:2006 Certified

- Medium to High Volume Production

Stop accepting “firm maybes” from your current supplier regarding on-time deliveries.

When reliability counts, accept nothing less.

Epcor has an exceptional history of maintaining casting supply when tooling is transferred to us. Our integrated quality driven processes include an in-house tooling facility and adapter plates which allow your patterns to seamlessly fit our machines.

Driving Production Forward With Advanced Technology to Deliver Highest Quality Castings

Challenge:

Designing a casting to meet your first time throughput requirements—out of the gate.

Process:

Epcor’s Engineering Team examines your casting with advanced simulation software to both guarantee results and craft out-of-the-box design solutions.

Result:

Shorter launch lead times, and better long-lasting casting.

Additionally, significant reductions in both internal scrap rates at Epcor Foundry as well as a reduction of external scrap at the customer are being realized.

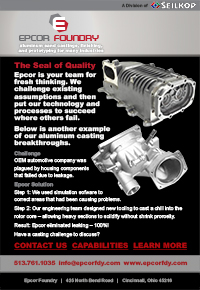

The Seal of Quality

Epcor is your team for fresh thinking. We challenge existing assumptions and then put our technology and processes to succeed where others fail.

Below is another example of our aluminum casting breakthroughs.

Challenge

OEM automotive company was plagued by housing components that failed due to leakage.

Epcor Solution

Step 1: We used simulation sofware to correct areas that had been causing problems.

Step 2: Our engineering team designed new tooling to cast a chill into the rotor core – allowing heavy sections to solidify without shrink prorosity.

Result:

Epcor eliminated leaking – 100%!

Foundry Robotic Systems

The harsh work environment in the foundry is like no other. It is exactly that demanding environment that has positioned foundries to be on the leading edge of robotic automation. All foundries contend with high temperatures and the inherent issues associated with pouring metal. Robots handle this in a repeatable fashion that makes the foundry more efficient, safer, and unfazed by the heat seen in production.

At Epcor, the benefits for adding robotic automation were considerable:

- Improved uptime on the production line

- Created a safer work environment

- Unmatched pouring consistency and accuracy

- Improved molding rates

Robotic automation also provides us with the flexibility to change – as your part requirements change.

Epcor for Faster Casting Delivery

Todays customer expect programs to be launched faster than ever!

do you need castings sooner?

WELCOME TO EPCOR FOUNDRY

When working with Epcor, you will experience a worry-free partnership from start to finish on new launches or transfer projects.

THE POWER OF ONE

The highest quality for machined castings happens when precision processes are performed under one roof.

Lowest cost US Productions Source

American Made, Globally Trusted & Lowest cost

- Epcor Foundry is your low cost U.S. source and proud to be 100% designed, engineered, and manufactured in our Cincinnati, Ohio production facility.

Prototyping-To-Cost Savings

Epcor's prototyping services lead to substantial cost savings. Read about our process to reduce prototype costs.

Epcor's Unmatched Casting Quality

Read about Epcor's Preventative Maintenance (PM) program that focuses on prevention over detection.

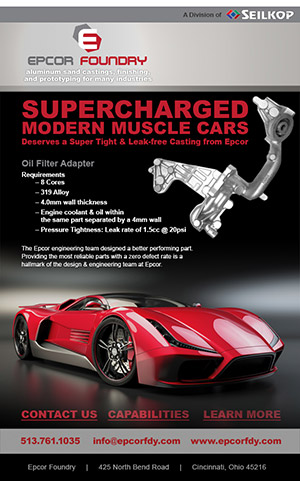

Supercharged Modern Muscle Cars

Read about how Epcor designed a better performing super light and leak-free casting for high performance automobiles.

Automated Processes and Why They Matter

Read about how Epcor’s automated process control ensures castings are made of the highest quality.

Get More Than Just the Best Aluminum Castings

Read about this Tier 1 automotive challenge that Epcor solved with a new gating system which eliminated leaks and scrap.

This is an ideal time to reshore your castings!

Epcor Foundry Installs Schaefer Furnace

Epcor Foundry, a division of Seilkop Industries recently installed a combination dry hearth and wet bath aluminum melting furnace from The Schaefer Group.

This gas fired furnace delivers degassed and filtered metal to the casting line – which gives Epcor the cleanest metal possible. The end opposite the dry hearth has a degassing unit and a filter with two electric elements in the ladle well end of the furnace, to maintain temperature stability during production.

"The Schaefer Combination Furnace gives Epcor the ability to produce higher quality parts more efficiently,” said Dave Seilkop, president of Epcor Foundry. “The unique ability of this energy saving combination furnace to also reduce metal loss with cleaner metal makes this an ideal choice for our aluminum part production,” he added. Installing the best equipment means producing better products at less cost for our customers – it's that simple!