Aluminum Castings

A High‑Performance Aluminum Sand Foundry

Epcor Foundry completed a multi‑million‑dollar equipment upgrade that expanded both capacity and process control across its Cincinnati, Ohio campus. The investment strengthened our position as a domestic aluminum sand foundry able to answer today’s demand for rapid launch programs and complex, highly‑cored components.

American‑Made Aluminum Sand Castings

Founded in 1946 and now a third-generation division of Seilkop Industries, Epcor delivers high‑quality aluminum sand castings to OEMs in the automotive, EV, fluid‑handling, marine and heavy‑truck sectors. From one-off prototypes to tens of thousands of pieces, customers trust us for on‑time shipments, tight process windows and competitive pricing.

Capacity & Facilities

Our Cincinnati operation spans tens of thousands of square feet and houses every step of the aluminum sand casting process under one roof. Automatic DISA Match and SINTO molding lines work in concert with robotic pouring systems, while PLC‑controlled sand preparation guarantees mold integrity. Multiple high‑capacity, gas‑fired reverberatory furnaces keep melt rates ahead of molding output, ensuring steady flow of certified metal.

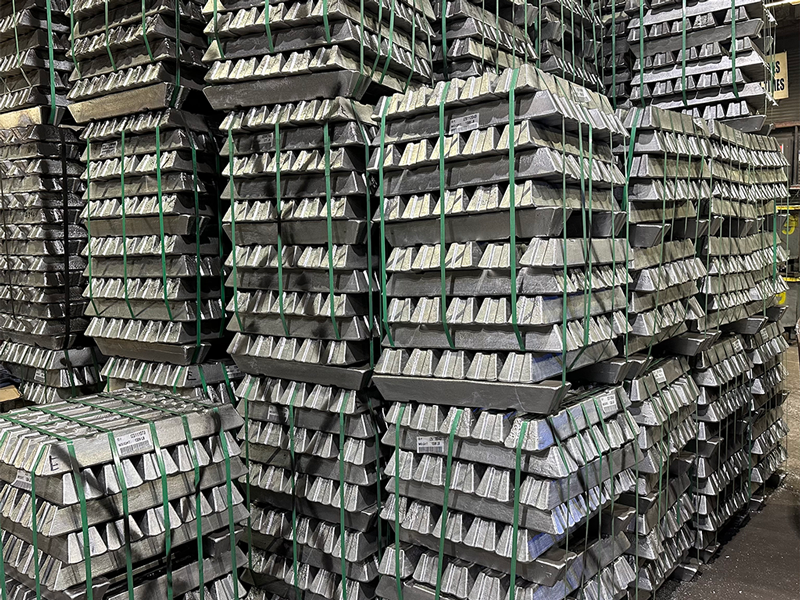

Alloys & Metallurgy

Epcor routinely pours 319, 356, 357 and other common foundry grades, and our in‑house spectrometer certifies each heat. Inline filtration and furnace-level temperature data collection further protect the chemistry and cleanliness of every aluminum sand casting.

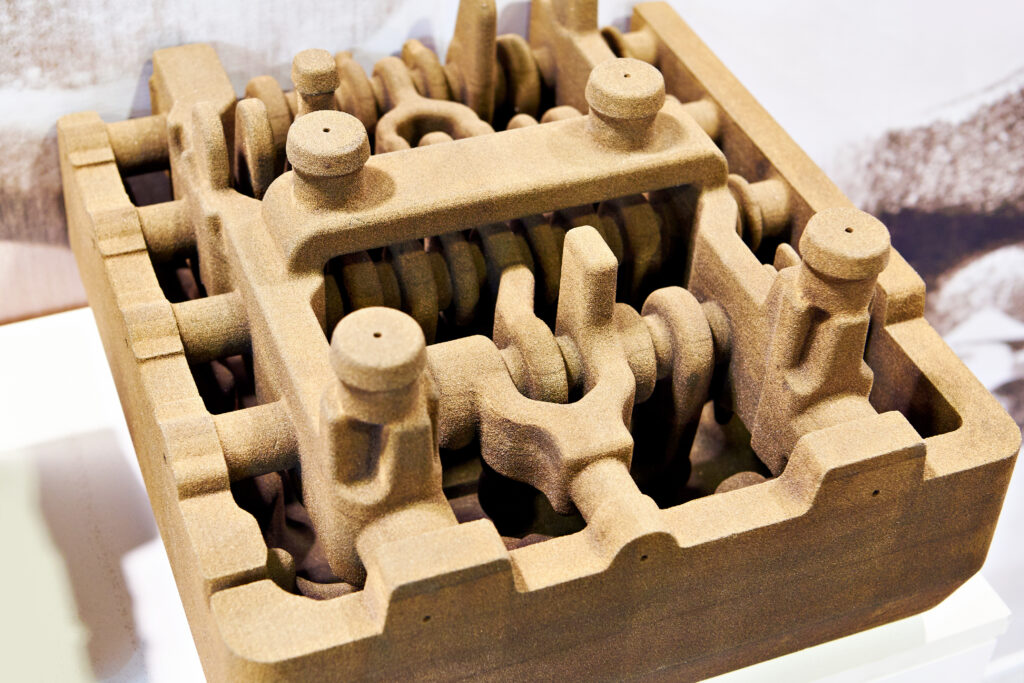

Tooling, Cores & Prototyping

Whether a project requires shell, cold‑box or oil‑sand cores, our dedicated core room supplies precise geometries that allow for leak-tight, highly‑cored aluminum castings. In-house simulation and rapid tooling shorten development cycles, letting customers move from prototype to production on a parallel path.

Finishing & Value‑Added Services

After shake‑out, castings move through 5‑axis CNC saws, automated trim cells, tumble blast, heat treat and machining centers. Painting, plating, assembly and JIT/kitted delivery are available so customers receive components that are production‑ready.

Quality Policy

Certified to ISO 9001:2015 and IATF 16949:2016, Epcor Foundry relentlessly improves every process to provide aluminum sand castings that consistently meet or exceed customer expectations for quality, price and delivery.