Capabilities

In addition to raw castings, we offer various machining and finishing services, such as decoring, CNC sawing, grinding, vibratory finishing, heat treating, machining, and plating. These services are completed with the same care and professionalism that has allowed us to grow into an industry leader as a casting supplier to many different industrial markets.

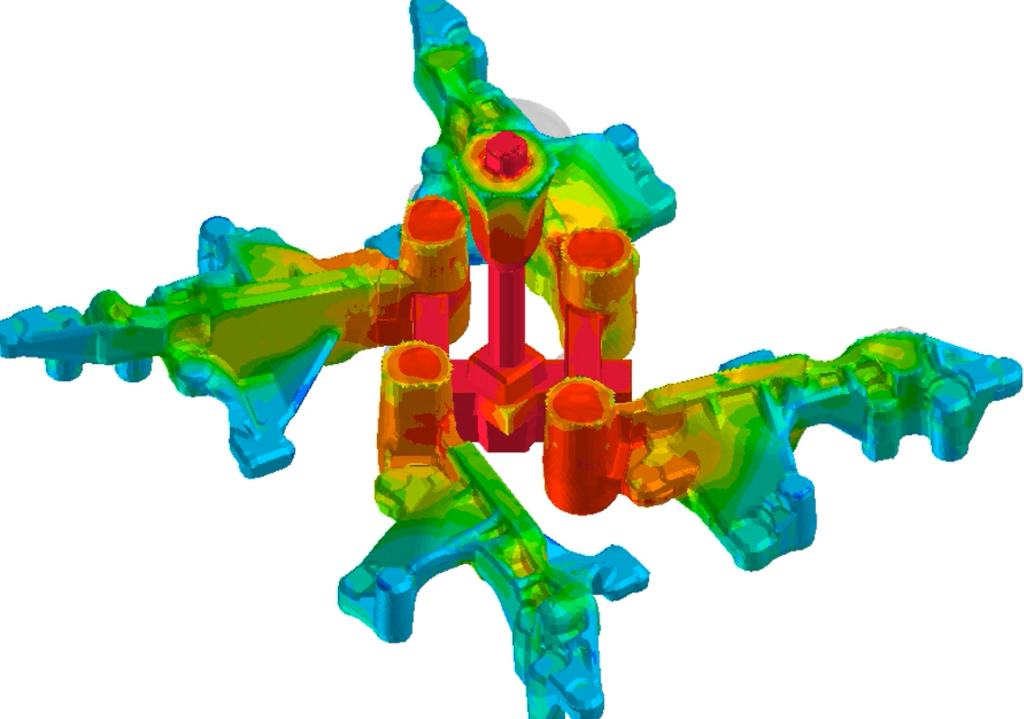

Simulation

Through advanced simulation software, we meticulously model and analyze every aspect of the casting process, ensuring accuracy and reliability in our predictions. These simulations empower us to hone our processes, leading to improved launch efficiency and reduced time to market. Clients can trust Epcor Foundry to deliver simulation solutions that drive efficiency, minimize costs, and ultimately result in superior aluminum castings.

Molding

Our automatic molding lines streamline production, ensuring consistency and repeatability with every mold. With melt rates surpassing molding output, we achieve peak throughput without compromising on the integrity of our products. The integration of robotic pouring further enhances our capabilities, ensuring uniformity and accuracy in every pour. Moreover, the tenure of our employees brings a wealth of knowledge and expertise to every project, guaranteeing that each casting meets your expectations.

Finishing

Epcor Foundry boasts an array of advanced production capabilities, including PLC-controlled core removal, 5-axis CNC saws, trim cells, tumble blasting, and meticulous inspection processes. With PLC-controlled core removal, we ensure precise and efficient extraction of cores from castings, enhancing overall quality and consistency. Our 5-axis CNC saws enable us to achieve intricate cuts on complex geometries with unparalleled accuracy. Trim cells further streamline our production process, allowing for efficient trimming and finishing of your components. Tumble blasting provides a uniform surface finish, while our rigorous inspection procedures guarantee the highest quality standards are met before components leave our facility.

Quality Systems

Epcor Foundry’s longstanding commitment to quality is evident through our ISO and IATF certifications, marking our adherence to rigorous international standards. With these certifications, we demonstrate our dedication to consistently delivering high-quality Aluminum Sand Castings to our customers. Our comprehensive lab capabilities enable thorough testing and analysis of materials and finished products, ensuring they meet the strictest quality criteria. Moreover, our implementation of PLC controls and monitoring systems throughout our production processes guarantees precision and reliability at every stage. At Epcor Foundry, our enduring commitment to quality systems ensures that our customers receive nothing but the best, in each container we ship to you.

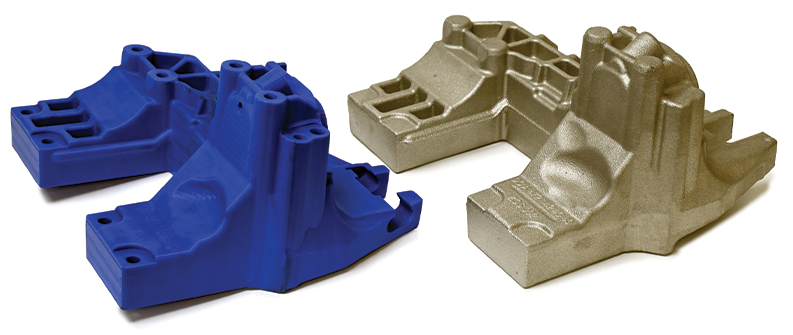

Prototyping

Our streamlined processes and cutting-edge technology enable us to expedite the prototyping phase, ensuring that your concepts are transformed into tangible components with unprecedented speed. By leveraging advanced simulation tools and agile methodologies, we can quickly refine prototypes, allowing for swift validation and adjustments if needed. With our parallel path to production approach, we effortlessly transition from prototyping to full production manufacturing, minimizing lead times and accelerating time-to-market for your products.

| Molding & Casting Services | Highly Cored Leak Tight Castings |

| Rapid Prototype Casting | |

| Additive Manufacturing | |

| Green Sand Casting | |

| High Speed Horizontally Parted Molding | |

| Robotic Pouring | |

| High Production Automation | |

| In-House Simulation and Tooling | |

| Product Capabilities | Heavy Castings |

| Large Castings | |

| Miniature | |

| Net Shape | |

| Small Components | |

| Casting Process | Chill |

| Continuous | |

| Counter Pressure | |

| Densification | |

| Gravity | |

| Impregnation | |

| Loose Pattern | |

| Pressure Tight | |

| Machines | DISA Match |

| SINTO | |

| Furnaces | |

| PLC Controlled | |

| Temperature Data Collection | |

| Sprinkler System | |

| In Furnace Filtration | |

| Sand Silo | 220 tons |

| Sand Preparation | PLC Controlled Continuous Mulling |

| Sand Screening & Aeration | |

| Complete Sand Lab | |

| Finishing Services | 5-axis CNC Finishing |

| Automated Saw/Trim Cells | |

| Trim Presses | |

| Casting Mold Type | Automatic Molding |

| Cope and Drag | |

| Casting Process Materials | Green Sand |

| Materials | Aluminum |

| 319 | |

| 356 | |

| 357 | |

| Tooling Material | Tooling for any Volume |

| Urethane | |

| Aluminum | |

| Steel | |

| Iron | |

| Mold Flask Length | Up to 24 in. |

| Mold Flask Width | Up to 20 in. |

| Additional Services Provided | CNC Machining |

| De-Coring | |

| Sawing | |

| Grinding | |

| Finishing | |

| Painting | |

| Assembly | |

| Tumble and Spinning Shot Blast | |

| Plating | |

| Heat Treating | |

| Inspection | Gage Control System |

| Part Scanning | |

| Coordinate Measuring Machine | |

| Spectrometer (Material Certification) | |

| Quality Control | ISO Certified |

| IATF Certified | |

| Full Sand Lab | |

| Traceability (Date Code System) | |

| SPC Tracking and Monitoring | |

| Testing | Cleanliness |

| Leak Tight | |

| Flow testing | |

| Production Volume | Low to High Volume |

| Prototype to Production |