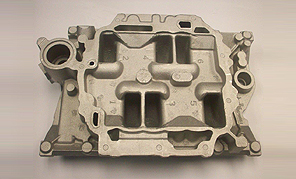

Casting of an Exhaust Gas Recirculation Duct & Air Intake Manifolds

At Epcor Foundry, a division of Seilkop Industries, Inc.,, we offer precision aluminum castings and casting design services which help our customers to develop high strength, economical castings. The project highlighted here was a redesign casting project for a tier one automotive supplier in the Southeast.

Their original design would have required a supplier to the truck industry, 15 cores, and would have been very costly to cast. We worked with them to redesign the part with a single core without affecting the performance of the part, this decreased the cost of the part tenfold. The 6” by 4” casting is composed of 356 aluminum, and cast utilizing our DISA Match 130 and Roberts Sinto FBO #3 20×24” high speed mold machines, this capability allowed us to meet tolerances of ±.010”. Quality control is maintained through dimensional, inspections as well as ball and flow checking. We redesigned this high volume production part and supplied it within budget and on time.

We currently cast approximately 185,000 of these parts annually, with a turnaround time of 10 weeks. For more information about this exhaust gas duct and air intake manifold project, see the table below, or contact us directly.

Air Intakes Manifolds EGR Ducts

Custom Manufactured Air Intake Manifold

Casting of an Exhaust Gas Recirculation Duct and Air Intake Manifold

Highlights of this Exhaust Duct & Air Intake Manifold Project

| Product Name | Manifolds and EGR Ducts |

| Product Description | This product is composed of exhaust gas recirculation ducts and air intake manifolds used on car engines. |

| Casting Capabilities Applied/Processes | |

| Primary: Casting De-Coring Automated Trim Cell | Secondary: Shot Blasting Packing |

| Equipment Used to Manufacture Part | DISA Match 130 & Roberts Sinto FBO #3 20x24" High speed mold machines |

| Overall Part Dimensions | 6" x 4" |

| Tightest Tolerances | +/- 0.010" |

| Material Used | 356 Aluminum |

| Material Finish | Color: Silver |

| In Process Testing/Inspection Performed | Dimensional Inspection, Ball Checking, Flow Checking |

| Industry for Use | Automotive Industry |

| Volume | 185,000 |

| Delivery/Turnaround Time | 10 Weeks |

| Delivery Location | Southeast |

| Standards Met | Customer Specifications, 2D CAD Drawing |