Casting of Aluminum Oil Filter Adapters / Coolers

At Epcor Foundry, a division of Seilkop Industries, Inc. we specialize in providing our customers with high quality complex aluminum castings. We received this project from a tier one automotive supplier. This casting is for an aluminum oil filter adapter/cooler. Production of this casting requires multiple assembled cores and uses fully machined steel pattern and core boxes. The finished part features dimensions of 6” x 6” x 20” and is cast from 319 aluminum.

We received this part as rush job because the customer’s previous supplier had gone out of business. Since our customer needed the parts immediately, the first run was produced with existing tooling while we developed the new tooling. With the use of our solidification simulation software we were able to anticipate machining challenges ahead of time, and discovered several areas of concern. This advanced capability allowed us to make key modifications that dramatically increased productivity. The first time through put exceeding 99%, compared to their former supplier’s through put which was below 80%.

Casting was performed on our DISA Match 130 and Roberts Sinto FBO #3 20×24” high speed mold machines, after de coring and trimming, the castings are shot blasted and heat treated, then run through a series of tests including dimensional and leak Inspection, as well as ball and flow checking, before packing and shipping to the customer. We currently manufacture 50,000 to 500,000 of these components annually, with lead times a shot as 4 weeks.

Our expertise in aluminum casting allows us to solve problems and provide complex aluminum castings that other manufacturers cannot provide. For more information about this oil filter adapter project, see the table below, or contact us directly.

Casting of Aluminum Oil Adapters

Complex Core Assemblies for Oil Filter Adapters

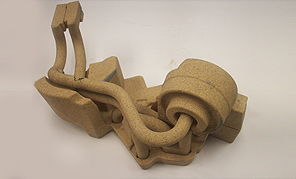

Complex Core Assembly for an Oil Filter Adapter

Highlights of this Aluminum Cast Oil Adapter/Cooler Project

| Product Name | Oil Filter Adapters / Coolers |

| Product Description | This is a complex part that circuilates oil and water to the cooler on car engines and requires multiple assembled cores and uses fully machined core boxes made from cast iron. |

| Casting Capabilities Applied/Processes | |

| Primary: Casting De-Coring Trimming Machining Threading | Secondary: Shot Blasting Heat Treating Packing |

| Equipment Used to Manufacture Part | DISA Match 130 & Roberts Sinto FBO #3 20x24" High speed mold machines |

| Overall Part Dimensions | Length: 20" Width: 6" Height: 6" |

| Tightest Tolerances | +/- 0.010" |

| Material Used | Aluminum A356 |

| Material Finish | Color: Silver |

| In Process Testing/Inspection Performed | Dimensional Inspection, Ball Checking, Flow Checking, Leak Testing |

| Industry for Use | Automotive Industry |

| Volume | 50,000 to 500,000 / year |

| Delivery/Turnaround Time | 4 Weeks |

| Delivery Location | Midwest & Great Lakes Region |

| Standards Met | Customer Specifications, 2D CAD Drawing |