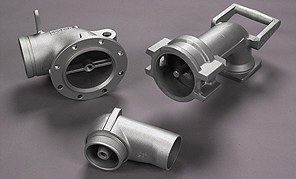

Casting of Aluminum Fueling Components

An industry leader in the fluid transfer component industry was on the brink of losing their customer’s business due to missed delivery dates, they counted on Epcor Foundry, a division of Seilkop Industries, Inc. to provide them with precision aluminum castings. Their previous castings supplier had provided them with poor quality castings, requiring them to scrap nearly 50% of the parts and fall behind on their production schedule. Scrap castings cost time and money in sorting and missing parts. We are able to provide the customer with castings at a scrap rate of less than 1%.

This casting is designed as a duct that dispenses fuel, used on heavy duty commercial trucks. We cast the parts from 319 and 356 aluminum and meet dimensional tolerances of ±.010” as specified by the customer. After casting and de-coring, the castings are machined in our automated trim cell before being put in the shot blasting machine and packed for delivery. For more information about this aluminum fuel component casting project, see the table below, or contact us directly.

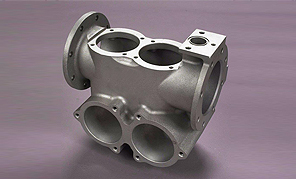

Fueling Component for Valve Pump Fluid Transfer

Highlights of this Aluminum Fuel Component Casting Project

| Product Name | Fueling Components |

| Product Description | These products are duct used on heavy trucks that dispense fuel. |

| Aluminum Casting Capabilities Applied/Processes | |

| Primary: Casting De-Coring Automated Trim Cell | Secondary: Shot Blasting Packing |

| Equipment Used to Manufacture Part | DISA Match 130 & Roberts Sinto FBO #3 20x24” High speed mold machines |

| Overall Part Dimensions | Up to 18” x 22” |

| Tightest Tolerances | +/- 0.010” |

| Material Used | 319 and 356 Aluminum |

| Material Finish | Color: Silver |

| In Process Testing/Inspection Performed | Dimensional Inspection, Flow Checking, Ball Checking |

| Industry for Use | Commercial Vehicle Industry |

| Volume | 5,000-35,000 |

| Delivery/Turnaround Time | 4-8 Weeks |

| Delivery Location | United States |

| Standards Met | Customer Specifications, 2D CAD Drawing |